Unveiling the Secrets: Just How Products Test Labs Make Sure Quality and Toughness

In the globe of production, ensuring the quality and resilience of products is critical. Through advanced techniques and advanced tools, products test labs examine the stamina and sturdiness of materials under various problems. By performing extensive tests, these labs make sure that the materials used in sectors such as construction, automobile, and aerospace meet the highest possible requirements of safety and security and longevity.

Importance of Products Screening

Materials testing plays an important role in guaranteeing the top quality and resilience of various items and parts. It is a vital action in the production process that helps identify any weak points or defects in products, permitting makers to make needed improvements before the products reach the marketplace.

Due to the fact that it aids identify if a material satisfies the called for requirements and specifications,One of the key reasons why materials testing is important is. Different sectors have specific needs for the products used in their items, and testing ensures that these requirements are fulfilled. This is especially important in markets such as aerospace, automotive, and building and construction, where security and dependability are of utmost significance.

One more secret element of materials testing is its ability to predict the efficiency and life expectancy of a product or element under various conditions. By subjecting products to different examinations, such as anxiety, rust, and temperature level tests, suppliers can precisely analyze how the materials will act in real-world circumstances. This allows them to make informed decisions regarding the viability and sturdiness of the products for their designated applications.

In enhancement to guaranteeing high quality and toughness, products testing also plays a vital function in r & d. It aids researchers and designers recognize the actions and homes of different materials, enabling them to develop innovative and brand-new items. Materials screening aids determine possibilities for expense reduction by optimizing product use and lessening waste.

Advanced Techniques and Tools

With the innovation of innovation and the enhancing demand for exact and accurate outcomes, products test laboratories have embraced innovative techniques and tools to make sure high quality and durability. These innovative methods and equipment have actually changed the area of materials screening, enabling for more exact and effective evaluation of numerous products.

One such method that has actually obtained substantial popularity is the use of innovative imaging innovations. High-resolution electronic cameras and microscopes are currently used to catch comprehensive photos of products at the tiny level. This makes it possible for scientists to research the internal framework and composition of products, identifying any type of issues or weaknesses that might affect their high quality and sturdiness.

Along with imaging modern technologies, materials test laboratories are additionally using innovative spectroscopic techniques. Spectroscopy includes the research of how materials connect with different wavelengths of light. materials test lab. By evaluating the light mirrored or absorbed by a material, researchers can get insights into its chemical structure and molecular framework. This details is essential in determining the material's performance qualities and viability for details applications.

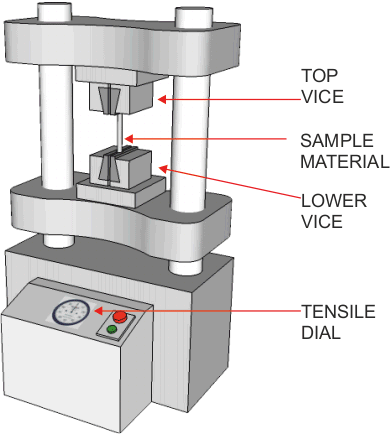

Additionally, products test laboratories are including advanced mechanical testing equipment into their workflows. These equipments can use regulated pressures, pressures, and temperature levels to analyze the product's mechanical residential properties, such as elasticity, solidity, and toughness. This allows scientists to assess just how a product will certainly endure various conditions and loads, guaranteeing its viability for a certain application.

Evaluating Toughness and Longevity

Making use of innovative mechanical screening equipment, products examination labs assess the strength and longevity of materials through controlled pressures, pressures, and temperature levels. These examinations are important in figuring out the material's capacity to stand up to different conditions and possible tensions it might run into during its life-span.

One common method made use of in materials evaluating laboratories is tensile testing. By measuring the applied force and the resulting contortion, scientists can determine the material's tensile strength, yield toughness, and prolongation buildings.

Along with tensile testing, materials test laboratories also perform solidity screening. This technique measures a material's resistance to imprint or scraping. By utilizing specialized instruments such as a hardness tester, the lab can establish the material's firmness value, which shows its capability to resist wear and deformation. This information is especially helpful in markets such as automobile and aerospace, where elements commonly experience high degrees of rubbing and effect.

In addition, products test labs evaluate the durability of products by subjecting them to different environmental problems. This might include direct exposure to severe temperatures, moisture, chemicals, or UV radiation - materials test lab. By replicating these conditions in a controlled fashion, researchers can assess the product's performance and predict its life expectancy under real-world problems

Replicating Real-World Problems

To accurately examine the performance and longevity of materials, materials examination laboratories employ regulated simulations of real-world conditions. By subjecting products to these designers, scientists and simulations can collect valuable information on exactly how products will behave in various settings and under different stress factors. Mimicing real-world conditions allows for a much more comprehensive analysis of a product's high quality and resilience.

One usual technique utilized by materials test laboratories is accelerated maturing screening. This entails exposing materials to elevated temperatures, moisture, and other elements that page simulate the aging process they would certainly undergo over an extended amount of time in the real world. try this By accelerating these processes, scientists can promptly assess a material's efficiency and forecast its lifespan in a shorter timeframe.

Along with increased aging testing, materials examination labs additionally imitate particular real-world conditions that products might run into. They might subject materials to extreme temperatures, high humidity, harsh atmospheres, or mechanical anxieties like flexing, extending, and effect. By reproducing these conditions in a regulated atmosphere, scientists can observe just how materials react and recognize potential weaknesses or locations for enhancement.

Imitating real-world problems allows materials test labs to offer producers and consumers with important information regarding a material's efficiency, integrity, and anticipated life expectancy. This understanding allows designers and engineers to make educated choices about the suitability of materials for different applications and make certain that items satisfy the needed top quality and durability standards.

Ensuring Safety and Long Life

Materials test labs make certain the security and longevity of materials by performing strenuous and extensive analyses of their efficiency and sturdiness. These evaluations entail subjecting the materials to various stress factors and problems to evaluate their ability to hold up against real-world situations. Safety is a leading priority in these analyses, as it guarantees that the products do not present any threats or risks to click this users or the setting.

In addition, materials examination labs utilize advanced methods such as increased aging and environmental chamber testing to imitate the effects of lasting exposure to rough conditions - materials test lab. These simulations aid anticipate the product's performance and lifespan, allowing suppliers to make educated choices about their items' safety and toughness

Conclusion

To conclude, materials examination labs play a critical role in making sure the top quality and toughness of various materials. With making use of advanced methods and tools, they have the ability to assess the stamina and durability of materials, along with simulate real-world conditions. By doing so, they contribute to making sure security and longevity in various markets.

By subjecting materials to different examinations, such as deterioration, temperature, and stress tests, manufacturers can accurately assess exactly how the materials will behave in real-world scenarios.Additionally, materials test labs review the resilience of materials by subjecting them to various environmental problems.To accurately assess the performance and long life of products, products test laboratories use regulated simulations of real-world conditions.In enhancement to sped up aging testing, materials examination laboratories likewise mimic particular real-world conditions that products may run into.In verdict, products test labs play an essential function in making certain the high quality and sturdiness of various materials.